Welcome to Shanghai Zhongyou Industrial Co., LTD. Website!

Welcome to Shanghai Zhongyou Industrial Co., LTD. Website! Welcome to Shanghai Zhongyou Industrial Co., LTD. Website!

Welcome to Shanghai Zhongyou Industrial Co., LTD. Website!Current Location:首页 > Product center > Rotary dehumidifier series > Mini wheel dehumidifier > KZHS-450 combined rotary dehumidifier

Brief description:Name: Combined rotary dehumidifier

Specification: KZHS-

Dehumidification capacity: kg/h

Applicable area: ㎡

Product features:

TRL series is a small rotary dehumidifier developed and produced by Shanghai Zhongyou Company, with all functions of dehumidification and ventilation, suitable for small air volume and small space humidity control occasions

Drainage method: rotary wheel

Machine shape: Aluminum alloy frame, its structure is tight, good sealing

Product model:KZHS-450

Product model:KZHS-450 Nature of manufacturer:manufacturer

Nature of manufacturer:manufacturer Update time:2024-05-16

Update time:2024-05-16 Number of enquiries: 1216

Number of enquiries: 1216Related article

Related ArticlesDetailed introduction

| 品牌 | ZHONGYOU/ Zhongyou | Application type | Other dehumidifiers |

|---|---|---|---|

| Type of instrument | Rotary dehumidifier | Category of origin | 国产 |

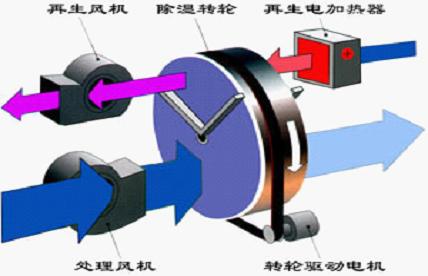

ZHONGYOU combined rotary dehumidifier principle:

As a rotary adsorption dehumidifier, its most important core component is a constantly rotating honeycomb silica gel wheel, which is synthesized by a special ultra-efficient hygroscopic medium material through more than 40 processing processes。The runner is a special honeycomb structure with equidistant, parallel and uniform air channels。In this way, the runner not only has a large surface area in contact with the air, but also improves the hygroscopic efficiency of the runner。

Part of the wheel in the dehumidifier is divided into a dehumidification treatment area of 270 degrees and a regeneration area of 90 degrees by a sealing plate, and the dehumidification wheel rotates slowly at a speed of 8 to 10 RPM to ensure that the whole dehumidification is a continuous process。

When treated air passes through the treatment area of the runner,The water vapor is absorbed by the hygroscopic medium in the wheel,Water vapor undergoes a phase change at the same time,Into liquid water,And release latent heat;At this moment,The treated air becomes dry air due to its own water reduction;later,The treatment air is sent out by the treatment fan,Into dry, hot air。

同时,In the regeneration area,The other air passes through the regenerative heater first,It becomes high-temperature air (generally 100 to 140 degrees) and passes through the wheel after hygroscopic,The water absorbed in the runner evaporates,As a result, the regenerated air is changed into wet air by the evaporation of water,At the same time the temperature drops;later,Then the wet air is expelled to the outside through the regenerative fan。

Recycled air (generally taken from outdoor or machine rooms) is heated to 100-130 ° C and blown into the regeneration area。The absorbed water in the silica gel is desorbed into water vapor, and the recycled air is discharged by the fan, thus completing the transfer of water from within the system to outside the system。After regeneration, the runner recovered the moisture absorption ability and transferred to the dehumidification sector to dehumidify again。

The above dehumidification and regeneration processes occur at the same time, and the cycle is repeated to ensure the continuous and stable working state of the dehumidifier。

Structural features:

◆ Aluminum alloy frame

Aluminum alloy frame, its structure is tight, good sealing。Double-layer insulation is adopted, the outer surface is sprayed with plastic, the inner surface is galvanized steel plate, and the middle is polyurethane material, which indicates the national standard heat transfer rate and anti-cold bridge to effectively prevent the phenomenon of "condensation"。

◆ Good wheel technology

The core technical component - hygroscopic runner, using the fifth generation of Europe - efficient titanium silicon compound runner。Its gluing rate is more than 82%, and it is widely used in various dehumidification requirements。

◆ Runner drive, sealing system

The imported drive motor and synchronous belt, coupled with the best self-tensioning, anti-lock bearing and contact sealing system, effectively ensure the stable and reliable operation of the runner。

◆ Reliable and flexible electrical control

All imported brand electrical components, reliable fault alarm and protection measures, leaving a remote communication interface, can be fully automatic control through DDC or PLC, and can be configured with touch screen or configuration software, to meet the requirements of industrial automation。

◆ Safe and diverse regenerative heating system

Regeneration can use electric heat pipe, steam heating, thermal oil coil, fuel direct combustion, natural gas direct combustion and other ways, the entrance adopts high temperature resistant aluminum filter, long life, easy maintenance。

◆ Precision sheet metal processing

Using dacheng high-quality steel plate, powerful imported CNC cutting plate, bending, punching and finishing center, rich galvanized, spray, paint and other surface treatment technology, to meet the different requirements of customers on appearance。

◆ Product Overview:

TRL series is a small rotary dehumidifier developed and produced by Shanghai Zhongyou Company, with all functions of dehumidification and ventilation, suitable for small air volume and small space humidity control occasions。

◆ Scope of use:

200 ~ 1500m3/h processing air volume。

Widely used in chemical, pharmaceutical, food, military, warehousing and museums, laboratories, substations, ship maintenance and so on。

TRL mini series rotary dehumidifier Main features: dehumidifier main components

◆ Imported high efficiency runner, stable dehumidification performance ◆ Long life, high efficiency, flushable high efficiency silicone runner

◆ Compact structure, floor, lifting and wall mounting ◆ imported runner motor, belt and drive system

◆ Regeneration adopts PTC control mode to ensure dehumidification accuracy ◆ Imported special high temperature and low leakage dehumidification sealing system

◆ Small size, light weight, easy maintenance, energy saving ◆ Germany EGO high temperature protection switch

◆ Nozzle, hose can be converted into mobile unit ◆ PTC or graded regenerative electric heater

◆ Adopt matte stainless steel plate or paint board, can stick insulation material ◆ Optional imported humidity sensor for humidity control

KZHS combined rotary dehumidifier performance parameter table:

Note: ◇ The data in the table is rated data, based on the air condition of 20℃, density 1.2kg/m3。

◇ Steam consumption according to 2108.4kJ/kg, gauge pressure 400kpa calculation。

◇ The above units are selected 200mm thickness HPS silicone runner imported from Sweden, other thickness requirements please call the company to explain。

◇ Dehumidifier power supply is 3V ~ 50Hz 380V。

Product consulting

Scan wechat